inadequate pneumatic cylinder stress can be caused by several factors related to the air deliver, cylinder situation, and device additives. beneath are the commonplace causes:

1. Air deliver troubles

Low Compressor Output: The air compressor might not be producing sufficient strain or quantity for the gadget.

pressure Drop: long air traces, undersized pipes, or immoderate fittings can motive a stress drop earlier than achieving the cylinder.

Clogged Filters or Regulators: dust, moisture, or oil buildup in filters and regulators can restriction airflow.

2. Air Leaks

Hoses and Fittings: damaged or unfastened air hoses, cracked pipes, or mistaken fittings can reason leaks.

Cylinder Seals: Worn or damaged piston or rod seals can result in internal leakage, lowering pressure.

Valves: Leaking or malfunctioning directional control valves can result in air loss.

3. glide restrictions

incorrect glide manipulate Valves: If the waft manipulate valve is about too restrictively, it is able to limit the air deliver.

Blocked Air strains: dirt, dust, or moisture buildup interior air strains can reduce airflow.

Small or Undersized components: A regulator, valve, or piping system that is too small won't deliver sufficient air.

4. excessive Load on the Cylinder

Overloaded Cylinder: If the implemented load is better than the cylinder’s capacity, it could no longer generate enough force.

Friction within the gadget: excessive friction due to misalignment or loss of lubrication can reduce performance.

5. defective Directional manipulate Valves

Improperly Sized Valves: A valve this is too small for the specified air extent can limit stress.

Sticking or Blocked Valves: Contaminants like dust or oil can motive the valve to paste or partly near.

6. Environmental factors

intense Temperatures: bloodless conditions can thicken lubricants and decrease air pressure performance.

Moisture contamination: Water in the air deliver can cause blockages and have an effect on the machine.

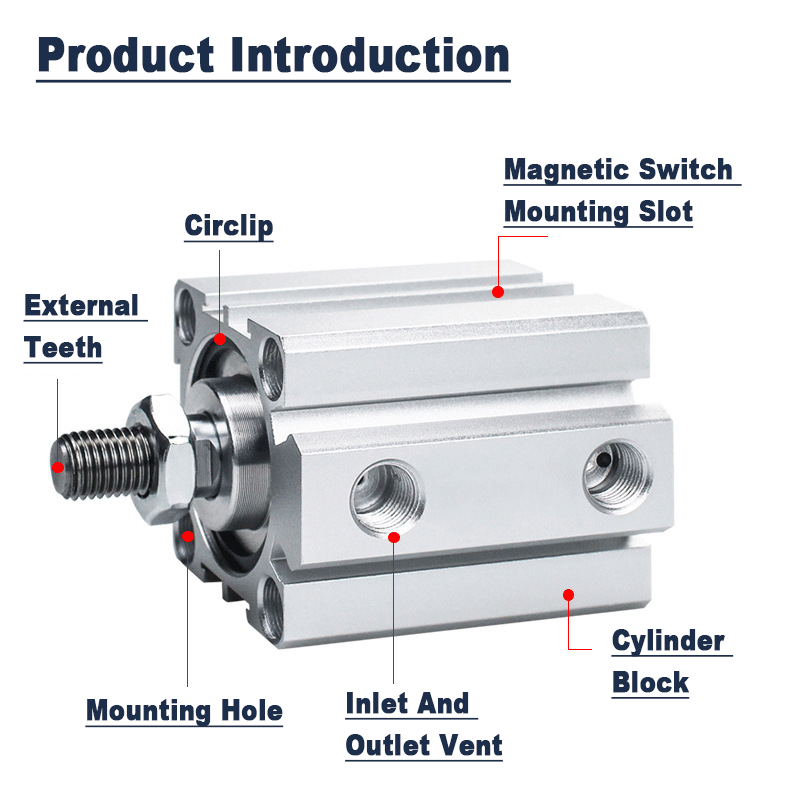

7. inner Cylinder issues

Worn or broken Piston Seals: Leaks within the cylinder can reduce stress output.

Bent or Misaligned Rod: A misaligned rod can create friction, stopping full extension or retraction.

the way to repair It

To resolve insufficient pneumatic cylinder pressure:

take a look at the air compressor and supply stress.

look at for leaks in hoses, seals, and fittings.

ensure valves, filters, and regulators are smooth and functioning.

verify the burden is within the cylinder’s ability.

verify correct alignment and lubrication of components.

would you like unique troubleshooting steps based totally on your setup?