①. introduction

The Pneumatic cylinder is a not unusual pneumatic actuator, broadly utilized in numerous commercial automation equipment. however, the problem that the cylinder is not in place is one of the commonplace faults, which severely influences the regular operation of the equipment. This paper will focus on the motives and standards of the cylinder is not in place.

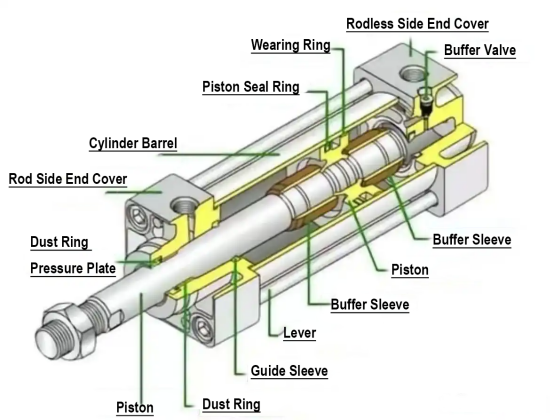

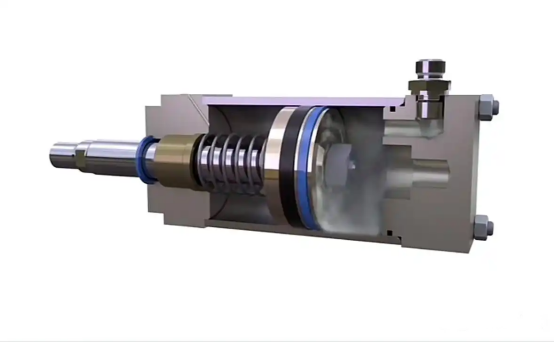

②.the working principle of the cylinder

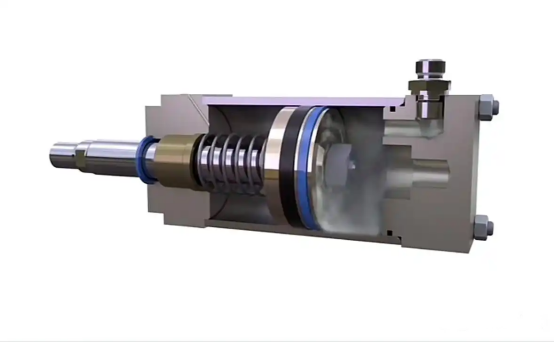

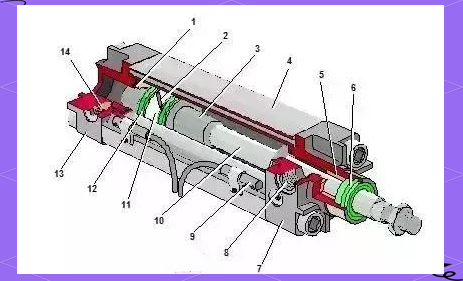

Cylinder is a linear motion mechanism pushed with the aid of air strain, and its running precept particularly includes the following points:

1. Air strain power: the piston and piston rod are furnished in the cylinder, and the piston movements within the cylinder through the air strain distinction, thereby driving the piston rod for linear movement.

2. function sensing: The cylinder is usually ready with a position sensor for real-time tracking of the location of the piston to ensure the accuracy of the piston within the preset function.

3. motion manage: by controlling the order and time of air intake and exhaust of the cylinder, the path and velocity of the piston may be managed.

4. Load edition: The cylinder can adapt to diverse forms of load, which include push, pull, rotation, and so forth., which makes the cylinder has a huge variety of applicability in various commercial programs.

③, the cause why the cylinder isn't always in location

The reasons why the cylinder isn't in vicinity can be summarized as follows:

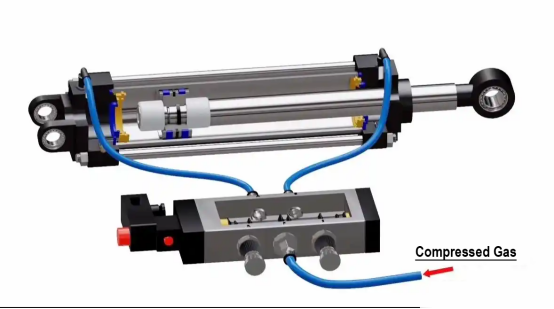

1. insufficient air stress: whilst the air supply pressure is lower than the specified pressure of the cylinder, the piston cannot reach the preset function.

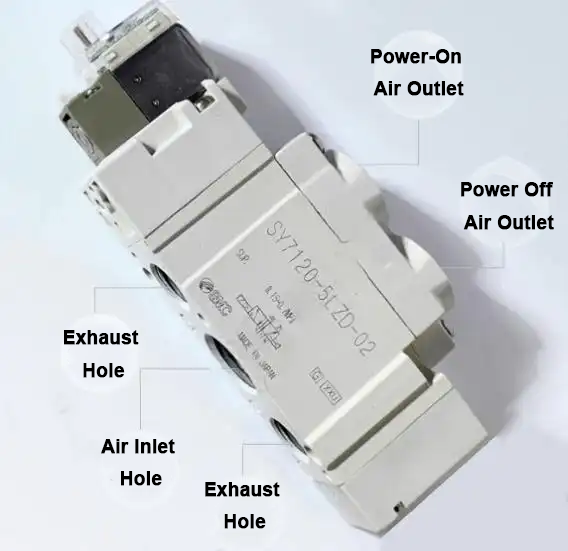

2. Air pipeline blockage: The pipeline among the air supply and the cylinder may be blocked, resulting in the failure of air pressure to transfer to the cylinder

3. Mechanical failure: The piston or piston rod is suffering from mechanical failure, inclusive of caught, put on, and many others., inflicting the piston to fail to reach the preset function.

4. role sensor fault: the position sensor can be faulty, together with cable damage or terrible touch, ensuing in inaccurate position feedback.

5. manipulate failure: The manipulate circuit or manage application fails, ensuing inside the failure to properly manipulate the movement of the cylinder.

④, the solution

To solve the above problems, the subsequent solutions may be adopted:

1. check the air source pressure: ensure that the air source stress meets the specified stress of the cylinder. If the air supply stress is insufficient, alter or update the air supply tool.

2. check the air pipeline: check whether the pipeline between the air supply and the cylinder is unimpeded to keep away from blockage affecting the gas transmission.

3. test mechanical faults: test the piston and piston rod. If mechanical faults including caught and put on are found, they ought to be repaired or replaced in time.

4. test the location sensor: take a look at and debug the position sensor to make sure that it really works typically and as it should be remarks the piston position.

5. take a look at the manage circuit and manage software: test and debug the control circuit and manage program to ensure that it really works generally and might successfully manipulate the motion of the cylinder.

⑤. conclusion

on this paper, the operating precept of the cylinder and the motives for no longer being in area are discussed in element. through know-how the operating principle of the cylinder and not unusual failure reasons, you could take suitable answers for restore and protection. In realistic programs, preventive protection and 86f68e4d402306ad3cd330d005134dac products must be emphasised to enhance the reliability of gadget and decrease the failure charge.