Analysis of differences and commonality between pneumatic solenoid valve and hydraulic solenoid valve

1. Comparative evaluation of pneumatic solenoid valve and hydraulic solenoid valve

There are sizeable differences between pneumatic solenoid valve and hydraulic solenoid valve in lots of aspects. those variations are not simplest pondered in their operating concepts, but also involve many factors consisting of utility situations, performance traits and generality. through exploring these variations extensive, we can gain a greater entire information of what makes those solenoid valves specific.

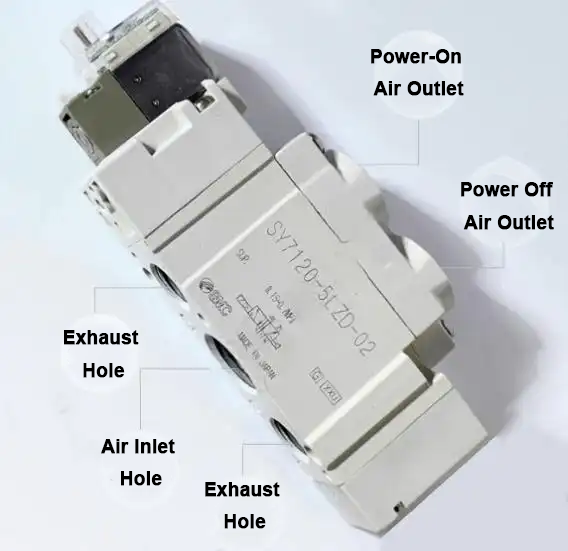

2, pneumatic solenoid valve

The solenoid valve, an commercial tool managed via electromagnetism, is the basic element of automation in fluid control. As an actuator, its application is not limited to hydraulic or pneumatic. In commercial manipulate systems, it plays a vital function in appropriately adjusting the route, go with the flow, pace and other key parameters of the medium. with the aid of cooperating with different circuits, the solenoid valve can achieve the favored manipulate effect, and its manipulate accuracy and flexibility are efficaciously guaranteed.

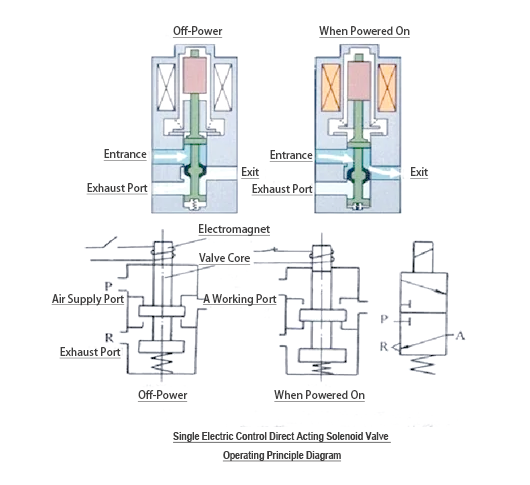

3, pneumatic valve

Solenoid valve, this business device controlled via electromagnetic, its operating precept lies in its internal closed chamber. The chamber is provided with through holes at specific places, every of that's connected with a particular oil pipe. A piston is positioned inside the middle of the chamber, that is equipped with electromagnets on each aspects. when the magnet coil on one facet is energized, the valve frame is drawn to that side, and the special oil discharge holes are opened or closed via controlling the movement of the valve body. because the oil inlet hole is always open, the hydraulic oil can enter the exceptional discharge tubing and push the cylinder piston via the strain of the oil. The movement of the piston similarly drives the piston rod, for that reason riding the motion of the mechanical tool. This way of controlling the mechanical movement by using controlling the present day of the electromagnet is also suitable for pneumatic structures.

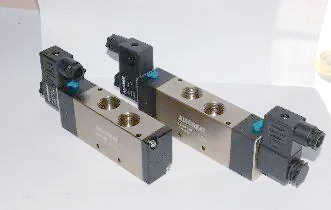

In manufacturing, we often use solenoid valves which include two three-way, two four-way and 5-manner and other types. So, what's the difference among pneumatic solenoid valve and hydraulic solenoid valve? certainly placed, the primary difference between the 2 is the type of fluid being controlled. Hydraulic solenoid valves are especially used to govern the strain and go with the flow route of oil, while pneumatic solenoid valves recognition on controlling the strain and flow course of compressed air. even though the 2 belong to the same class of fluid valves, and the operating principle is similar, they may be no longer everyday.

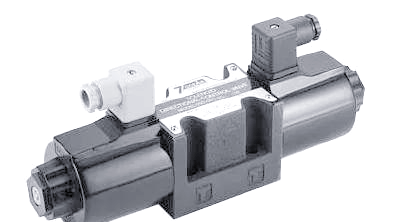

4, hydraulic valve

Hydraulic valve, as a key thing in the hydraulic system, its role is to manipulate the stress, drift and course of the hydraulic machine. via converting the placement of the spool, the fluid inside the hydraulic device can be precisely controlled. similar to solenoid valves, hydraulic valves additionally have a diffusion of types, which includes test valves, reversing valves, etc., to satisfy different control needs. In hydraulic structures, the synergy of these valves guarantees the solid operation and efficient performance of the gadget.

5, pneumatic solenoid valve and hydraulic solenoid valve why no longer established?

There are giant differences in the design of pneumatic solenoid valves and hydraulic solenoid valves, which reason them to be incompatible. although these solenoid valves are used to govern fluids, the fluid residences, working pressures and set up environments they follow are one-of-a-kind. consequently, the selection have to be differentiated consistent with the specific software scenarios to make certain the regular operation of the device and the full play of performance.

6. power variations

The pneumatic solenoid valve typically adopts the mode of centralized fuel deliver inside the air compressor station, and the running stress of the stress lowering valve is adjusted to meet distinctive use needs and manipulate points. The hydraulic solenoid valve is supplied with a go back oil line for collecting the used hydraulic oil returned to the tank. similarly, the pneumatic control valve is prepared with an exhaust port to discharge compressed air at once into the environment.

7, leakage requirements distinction

Hydraulic valves have strict necessities in phrases of leakage to the outdoor, but small amounts of leakage inside the components are allowed. In evaluation, pneumatic manage valves are specific, similarly to the distance sealed valve, different types of valves in principle do no longer permit inner leakage. that is due to the fact the inner leakage of the pneumatic valve is liable to causing an twist of fate. on the other hand, the pneumatic pipe can permit a mild leak, but the leaka

8, lubrication call for distinction

The hydraulic device uses hydraulic oil because the operating medium, so the hydraulic valve has no unique lubrication requirements. The pneumatic gadget makes use of air because the running medium, due to the fact the air lacks lubricity, so most pneumatic valves need to be lubricated via oil mist. to be able to make certain the normal operation of pneumatic valves, all pneumatic systems are equipped with pneumatic triplets. further, the elements and components of the valve need to be proof against water corrosion, or take appropriate anti-rust measures to ensure its long-time period reliability.

8, lubrication demand difference

The hydraulic system uses hydraulic oil as the working medium, so the hydraulic valve has no specific lubrication requirements. The pneumatic system uses air as the working medium, because the air lacks lubricity, so most pneumatic valves need to be lubricated by oil mist. In order to ensure the normal operation of pneumatic valves, all pneumatic systems are equipped with pneumatic triplets. In addition, the parts and components of the valve should be resistant to water corrosion, or take appropriate anti-rust measures to ensure its long-term reliability.

9, stress range distinction

The operating stress variety of pneumatic valves is lower than that of hydraulic valves. usually, the working strain of pneumatic valves is limited to 10bar (that is, 1Mpa), and some excessive-overall performance pneumatic valves can be able to face up to stress up to 40bar. but, the running pressure of hydraulic valves is often better, usually no longer extra than 50Mpa. If the pneumatic valve is used in excess of its maximum permissible stress, it is in all likelihood to purpose serious injuries.

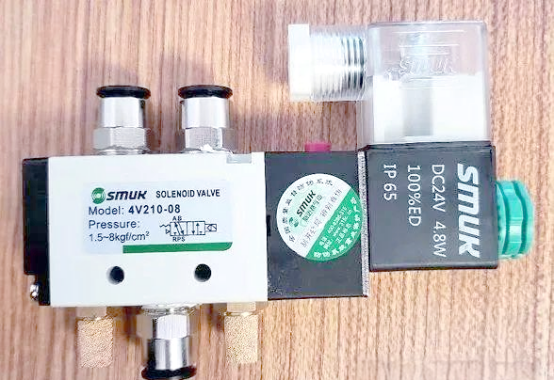

10. variations in utility characteristics

Pneumatic valves generally have the advantage of being compact and lightweight, which makes them fantastic for included set up. on the same time, the pneumatic valve has a excessive working frequency and a protracted carrier lifestyles, which meets the desires of various business programs. With the development of generation, pneumatic valves are developing inside the course of low strength and miniaturization, and now extremely-low electricity solenoid valves with a electricity of simplest zero.5W have appeared. further, the pneumatic valve also can be at once connected with the microcomputer and p.c programmable controller, and even established collectively with digital devices at the revealed circuit board, through the standard board can without difficulty connect the air flow circuit, simplifying the wiring process, very appropriate for pneumatic business manipulators and complex production assembly lines and other scenes.