The running precept of a pneumatic valve is primarily based on controlling the float of compressed air or gasoline to modify the operation of pneumatic structures, which includes actuators, cylinders, or gear. here's an in depth clarification:

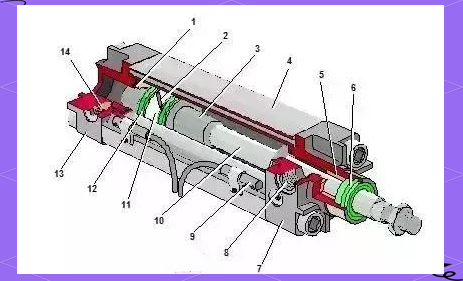

Key additives:

Valve body: homes the waft passages and ports.

Actuator: Converts the manage signal into mechanical motion (can be guide, pneumatic, or solenoid-operated).

waft Ports: Inlet, outlet, and on occasion exhaust ports for the air or fuel.

Seals and Seats: save you leaks whilst the valve is closed.

manage sign: input to direct the valve's operation (e.g., electrical sign for solenoids or pressure signal in pneumatic actuators).

operating Steps:

supply of Compressed Air:

Compressed air or gas is furnished to the inlet port of the valve.

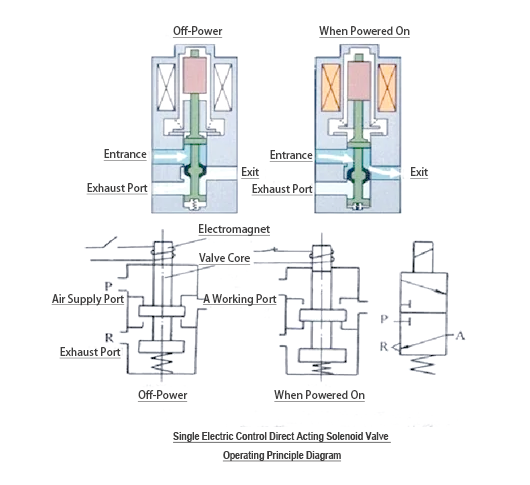

manage input:

The valve gets a manage sign to determine its operation. This sign can be:

Mechanical: Actuated by means of a lever or button.

Pneumatic: Air pressure from a pilot line controls the valve.

electric: A solenoid converts electric electricity into movement.

inner Mechanism Actuation:

The control sign movements an inner thing, which include a spool, diaphragm, or poppet, to direct the airflow.

for instance:

In a 2-manner valve, the internal mechanism opens or closes a unmarried float route.

In a 3-way or 4-manner valve, the internal mechanism alternates the air's path between unique ports.

Airflow law:

depending on the internal mechanism's position, the valve lets in, blocks, or redirects airflow to the output port.

as an instance:

In a four-way valve, compressed air would possibly glide to extend a cylinder, whilst the exhaust air is simultaneously launched via some other port.

go back to Default position:

when the manage signal is eliminated, the valve generally returns to its default (open or closed) position using springs or a pilot signal.

Key principles at Play:

stress Differentiation: Air flows from excessive-stress to low-strain areas while the valve opens.

manipulate Mechanism: Determines whether or not the valve stays usually open (NO) or normally closed (NC).

Exhaust Ports: allow used air to escape, ensuring proper function in multi-manner valves.

programs:

Directing air to operate pneumatic cylinders and actuators.

Controlling airflow in industrial machinery.

managing air deliver in HVAC structures or computerized production traces.

by exactly controlling the glide of compressed air, pneumatic valves make certain green and accurate operation of pneumatic structures.