A 5/2 way valve is a type of pneumatic directional control valve commonly used to direct the flow of compressed air in pneumatic systems. Its name reflects its design and functionality:

Key Characteristics:

5 Ports:

- The valve has five ports:

- Two ports (A and B) for connecting to the actuator (e.g., a double-acting cylinder).

- One port (P) for the compressed air supply.

- Two exhaust ports (R1 and R2) for venting the air from the actuator.

- The valve has five ports:

2 Positions:

- The valve has two distinct positions, which determine the direction of airflow and which ports are connected.

Functionality:

- In one position:

- Compressed air flows from the supply port (P) to one actuator port (A), while the other actuator port (B) is connected to its exhaust port (R1).

- In the other position:

- The flow is reversed: compressed air flows from the supply port (P) to the other actuator port (B), while the first actuator port (A) is connected to its exhaust port (R2).

Usage:

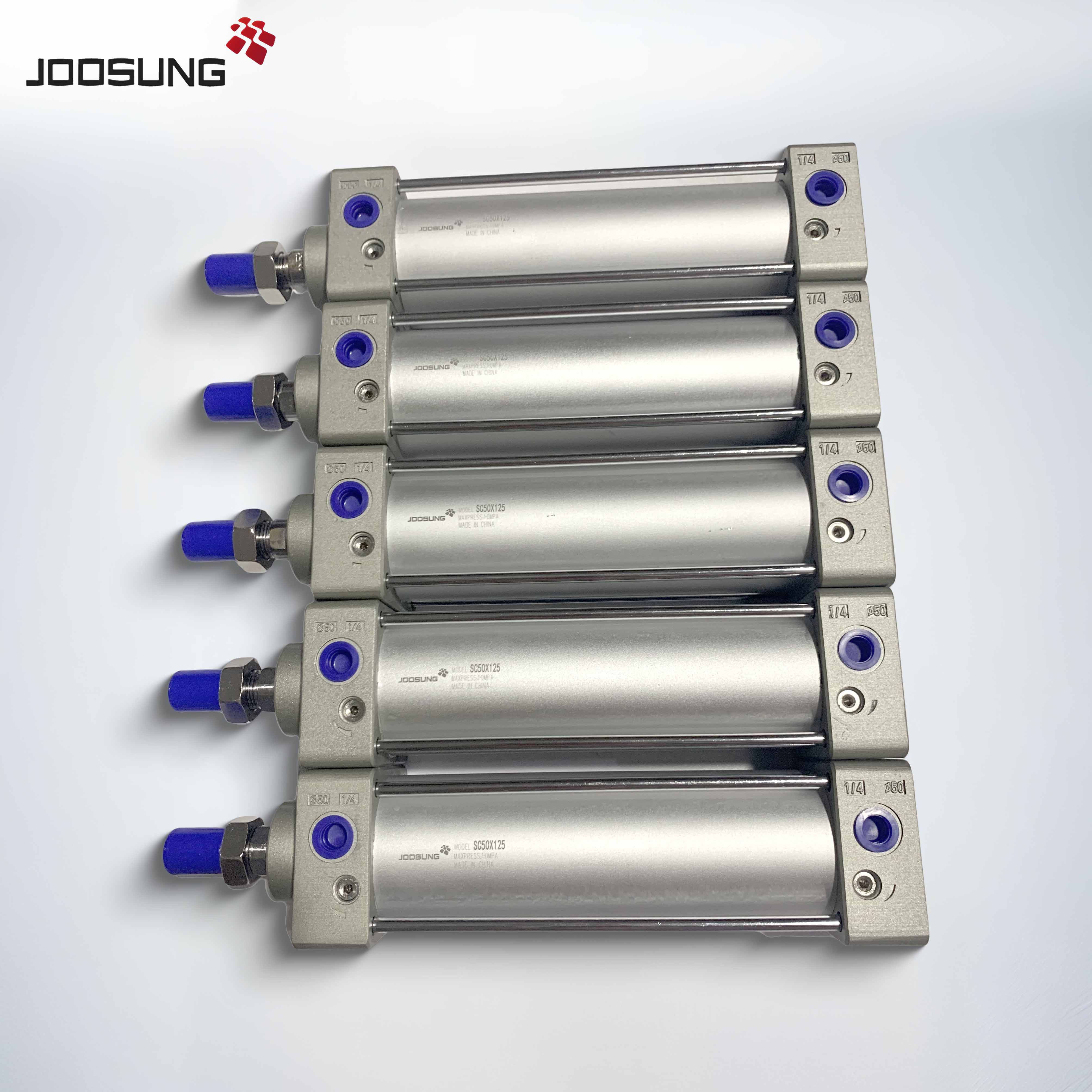

- Double-acting cylinders: It is used to alternate the cylinder's extension and retraction by controlling the air direction.

- Actuation Methods: The valve can be operated manually, mechanically, electrically (solenoid-actuated), or pneumatically.

Applications:

- Commonly used in industrial automation, robotics, and machinery requiring precise and efficient pneumatic actuation.