1.Code description

Give an example:4v-1 10 06 AC 10V

Instructions:

|

CODE |

significance |

remark |

|

4v |

The number indicates the number of entrances and exits |

3V: Three-way port solenoid valve 4V: Square solenoid valve 5V: Five square port solenoid valve |

|

1 |

series |

1:100series 2:200series 3:300series 4:400series |

|

10 |

type |

10:Single coil double position 20:Double coil double position 30C : Double coil three position closed type 30E: Double coil three position open 30P : Double coil three position pressure type |

|

06 |

Nozzle diameter |

M5:M5*0.8 06:PT1/8 08:PT1/4 10:PT3/8 15:PT1/2 |

|

AC 10V |

Standard voltage |

DC12V:DC 12V DCD4V:DC 24V AC24V:AC 24V50/60Hz AC10V:AC 110V50/60Hz AC220V:AC 220V 50/60Hz AC380V:AC 380V50/60Hz |

2、Indicator specification

|

specification |

Instructions | |

|

Working fluid |

Air (40μm filter) | |

|

Actuating mode |

Internally guided | |

|

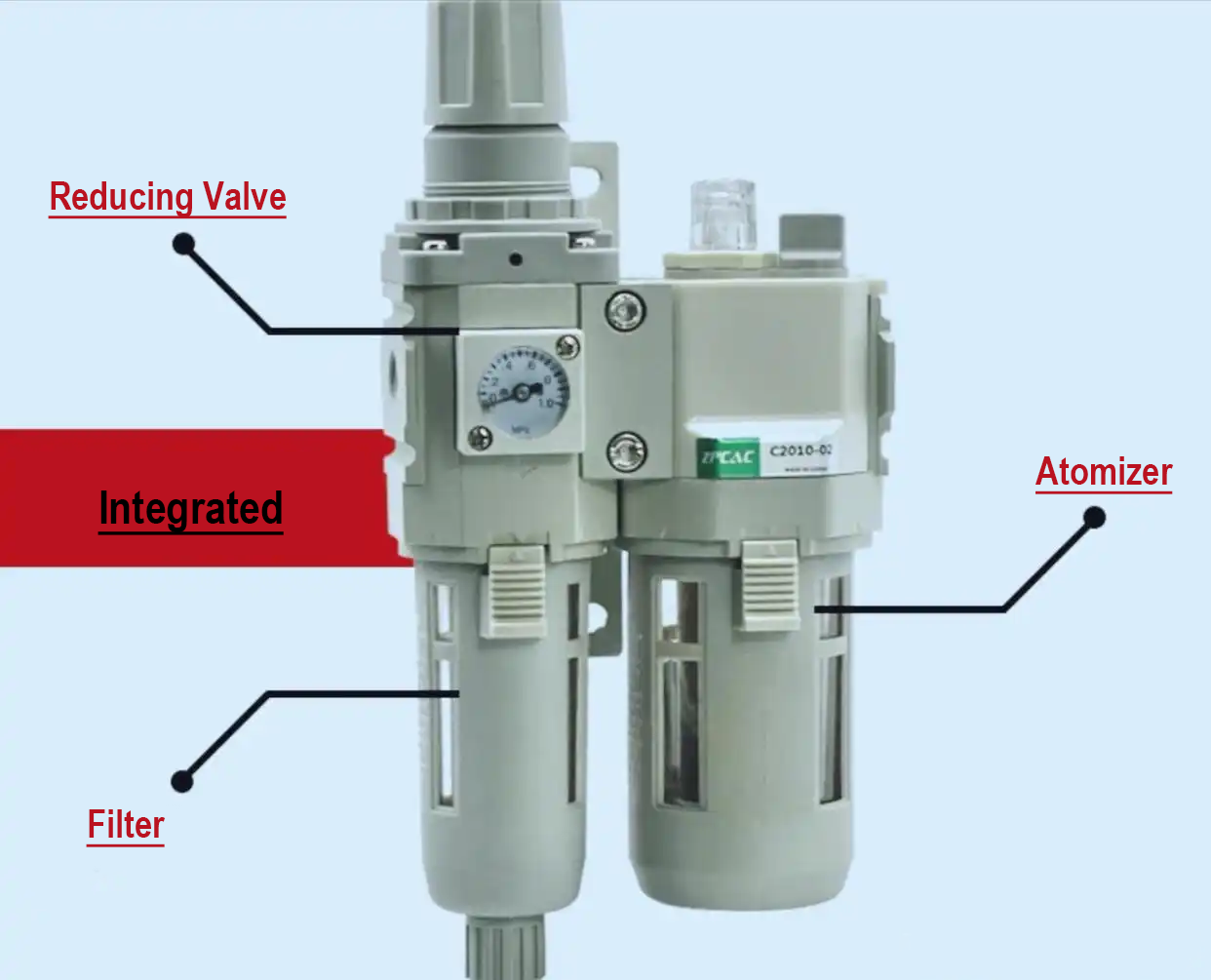

oiling |

Not required (appropriate lubrication to improve service life, recommended lubricating oil ISOVG32) | |

|

Operating pressure (Kgf/cm²) |

1.5~8.0 | |

|

Operating temperature |

-5~60 | |

|

Maximum pressure resistance |

12 | |

|

Voltage range |

100 series |

±10% |

|

2、3、4 series |

-15%~+10% | |

|

Power consumption |

100 series |

DC:2.5W,AC:3.0VA |

|

2、3、4 series |

DC24V:3.0W,ACBD20V:2.0VA, | |

|

insulativity |

F | |

|

Service life |

More than 10 million times under normal use | |

|

Maximum operating frequency |

3V1/2/300series |

5 |

|

4V100series |

4V110、4V120type:5,4V130type:3 | |

|

4V200series |

4V210、4V220type:5,4V230type:3 | |

|

4V300series |

4V310、4V320type:5,4V330type:3 | |

|

4V400series |

4V410、4V420type:5,4V430type:3 | |

|

Excitation time |

0. 05 | |

3、Simple authenticity identification and comparison:

|

Check item |

The genuine |

sham |

|

Pilot head part |

smoother |

rough |

|

Trademark section |

tidiness |

irregularity |

4、Usage and maintenance instructions:

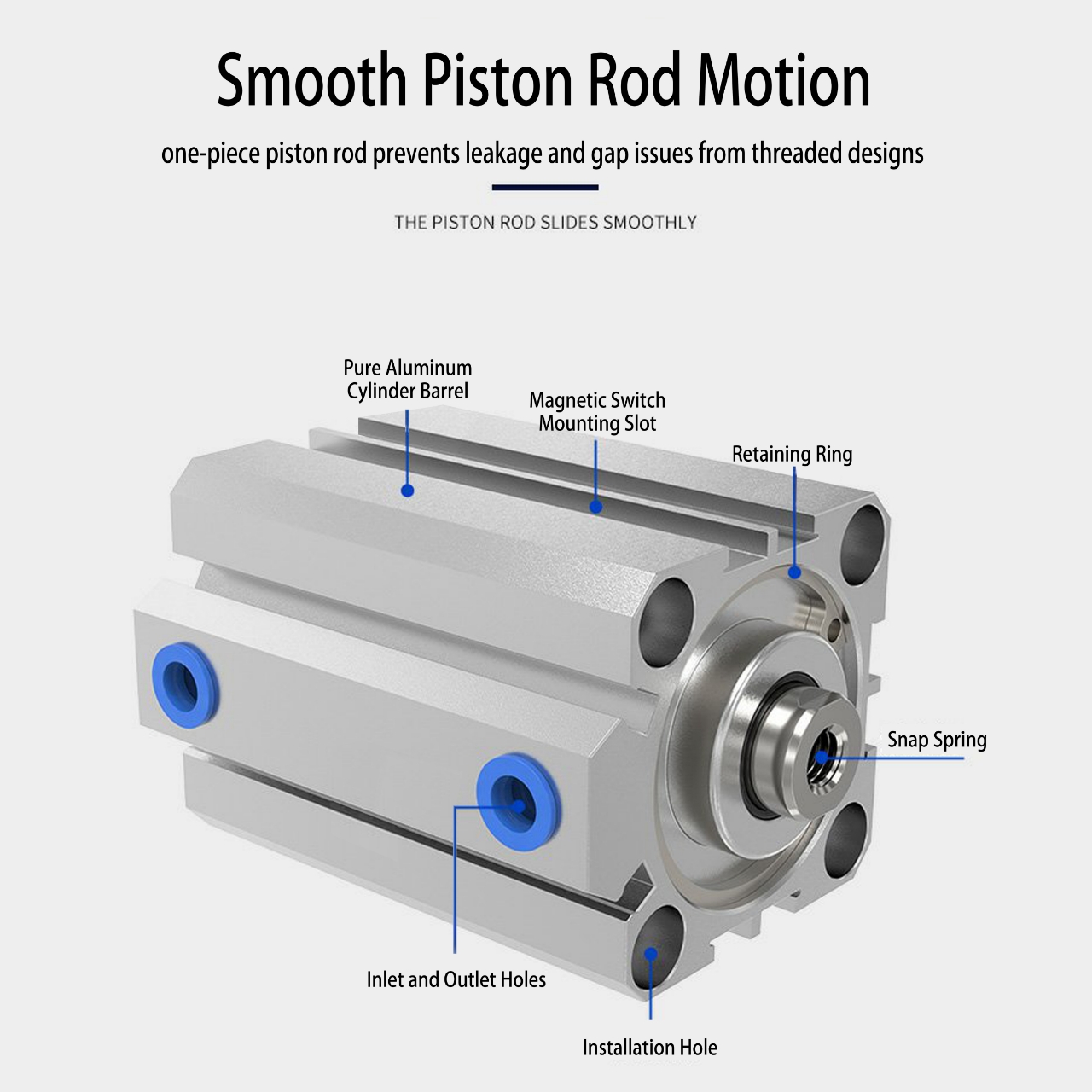

(1)Pay attention to check the components before use, whether they are damaged during transportation, and then install and use.

(2)When installing, please pay attention to the correct direction of gas flow and nozzle.

(3)When using, please strictly comply with the technical requirements, such as working voltage, operating frequency, working pressure, and operating temperature: When debugging the whole machine, it is recommended to use manual device debugging, and then power debugging.

(4)Please pay attention to dust, it is recommended to install a muffler or muffler throttle valve at the exhaust port

(5)When connecting pipelines, pay attention to the winding of the stop belt (raw material belt) shall not exceed the threaded end face of the joint, and pay attention to the elimination of metal particles, dust and oil in the joint and pipe