A pneumatic valve works by controlling the float of air or gas in a pneumatic gadget to operate various components like actuators, cylinders, or tools. The primary characteristic is to open or near the valve to allow or forestall the float of compressed air. here's a breakdown of ways it works:

1. Solenoid Actuation:

Solenoid valves are normally used in pneumatic structures and are electrically controlled.

The valve is activated through an electromagnet (solenoid), which, when energized, actions a valve mechanism to manipulate airflow.

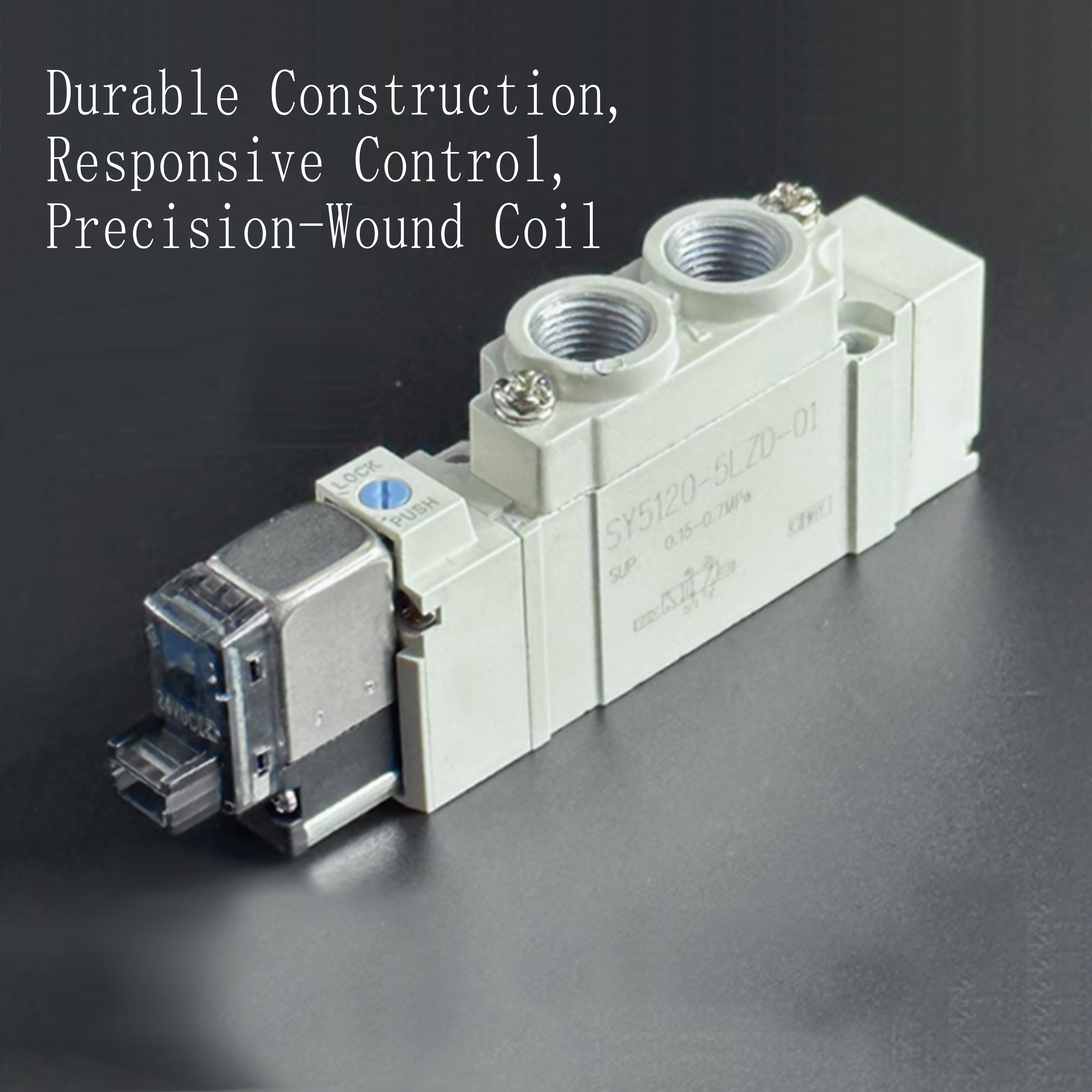

2. Valve additives:

an average pneumatic valve has numerous key components:

Solenoid Coil: The coil creates a magnetic field when energized.

Armature: A steel piece this is pulled or driven by the solenoid's magnetic discipline to open or near the valve.

Valve body: The housing that incorporates the inner components of the valve.

Ports: The enter and output channels wherein compressed air enters and exits the valve.

Spring: A go back spring that resets the valve to its default role when the solenoid is de-energized.

3. sorts of motion:

Pneumatic valves may have exceptional configurations relying at the variety of ports and positions. commonplace types are:

2/2 Valve: A two-port, -function valve (often a simple on/off valve).

three/2 Valve: A 3-port, two-position valve used to control a single actuator in a fundamental device.

five/2 Valve: A 5-port, two-function valve often used in double-acting actuators.

4. the way it Works:

while Energized: when an electrical present day is implemented to the solenoid coil, it creates a magnetic area that moves the armature. This movement opens or closes the valve, directing the airflow to the desired port. In some instances, it may exhaust air from a specific port or supply air to a machine element.

while De-energized: when the solenoid is de-energized, the spring or a mechanical force returns the valve to its default position, blocking or redirecting the air flow.

5. manage of Airflow:

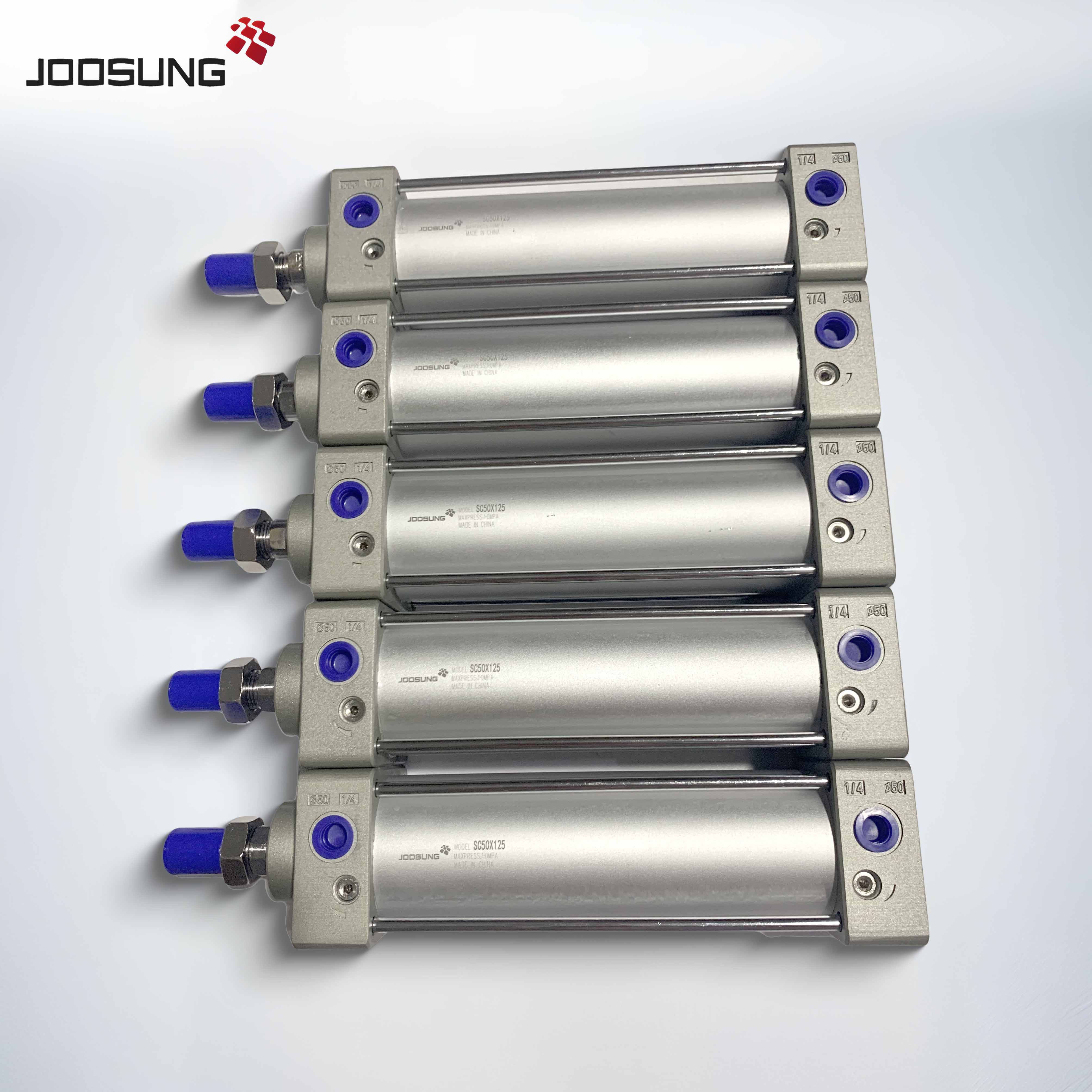

The valve allows air to flow into or out of particular parts of the device, controlling the action of actuators. for instance, it can control a cylinder's movement, consisting of extending or retracting.

In a 3/2 valve, one port normally connects to the air supply, another to the actuator, and the 0.33 port is used for exhaust.

In a five/2 valve, the extra ports allow for greater complicated manipulate, like reversing the movement of a double-performing actuator.

6. packages:

Pneumatic valves are widely utilized in commercial automation, robotic systems, packaging machines, and any other gadget that uses compressed air to carry out paintings.

In essence, a pneumatic valve acts as a controlled gate for compressed air, and by means of energizing or de-energizing its solenoid, it both directs air to specific machine components or exhausts it to modify operation.