The principle of a pneumatic solenoid valve is based totally on using an electromagnetic force to govern the waft of compressed air or fuel in a pneumatic machine. essentially, the solenoid valve acts as a transfer, opening or last an air passage primarily based at the activation of an electromagnet. here is a step-with the aid of-step breakdown of the operating precept:

1. Electromagnetic Activation:

The solenoid valve consists of an electromagnet (solenoid coil) this is energized by means of an electrical modern.

when the current flows via the solenoid coil, it generates a magnetic discipline. This magnetic subject creates force that moves a metal piece known as the armature.

2. Armature movement:

The armature, typically a movable metal part, is both pulled or driven through the magnetic area of the solenoid.

This movement of the armature opens or closes inner passages in the valve, allowing or blockading the drift of air (depending on whether or not the valve is designed to be generally open or commonly closed).

three. Valve Positions:

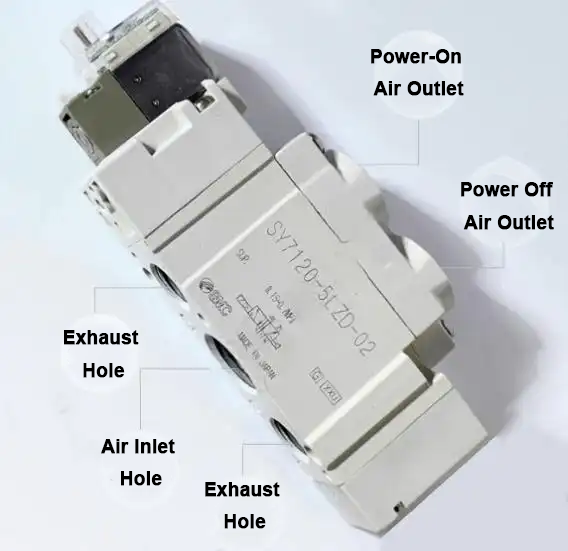

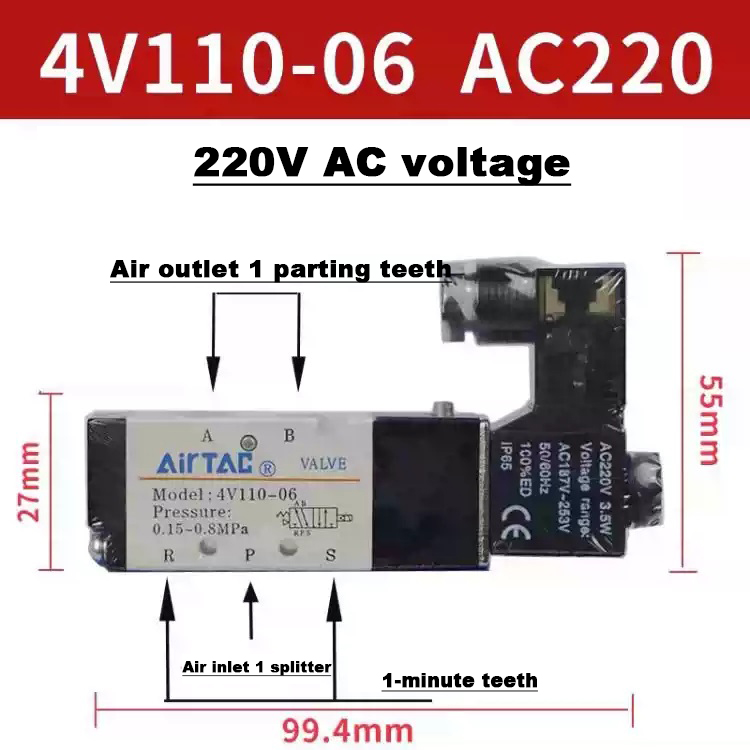

Pneumatic solenoid valves may have diverse designs, such as 2/2, three/2, or five/2 configurations, which seek advice from the quantity of ports and the number of valve positions.

2/2 Valve: ports and two positions (normally used for on/off manage).

3/2 Valve: 3 ports and positions (used to control a single actuator or cylinder).

five/2 Valve: five ports and two positions (generally used for double-appearing actuators).

four. flow control:

depending at the valve configuration, when the solenoid is energized (coil activated), the armature both:

actions to attach or disconnect the air supply to the actuator.

Directs the airflow from one port to any other.

Exhales the air from the gadget or actuates a cylinder to increase or retract.

when the solenoid is de-energized (no modern-day), a go back spring (in many solenoid valve designs) forces the armature returned to its default position, preventing or redirecting the air drift as wished.

five. kinds of control:

typically Closed (NC): The valve stays closed while the solenoid is not energized, blocking air flow. whilst the solenoid is energized, the armature movements to open the valve and permit air go with the flow.

usually Open (NO): The valve remains open whilst the solenoid is not energized, permitting air to pass thru. when the solenoid is energized, the armature moves to shut the valve, preventing the air waft.

6. Key functions:

The valve can be used to start, stop, or direct the flow of air to exclusive components inside the pneumatic device.

brief reaction time: Solenoid valves provide rapid actuation, making them ideal for controlling pneumatic cylinders and actuators that require speedy movement.

electric manipulate: due to the fact solenoid valves are electrically managed, they may be easily included into computerized structures.

summary:

The basic working precept of a pneumatic solenoid valve is that an electromagnetic field created via a solenoid coil moves an armature to open or close inner valve passages, thereby controlling the go with the flow of air in the machine. while energized, the valve directs or shuts off air waft, and while de-energized, it returns to its default function, permitting or blocking the air go with the flow consequently. This makes it an important component in pneumatic systems for controlling automated processes.