Pneumatic solenoid valve is always faulty, a way to deal with it correctly?

with regards to solenoid valves, they're now very common in commercial packages, mainly in the petroleum and chemical industries, many technique pipelines must set up on-off valves, and because the paintings site may be very risky, the protection requirements are greater stringent than different industries, massive chemical corporations have specialised instrumentation employees, and small electricians are basically accountable for every day control and preservation.

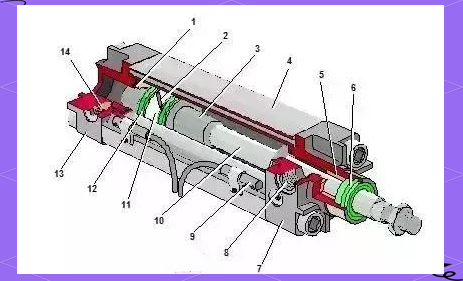

right here is the pneumatic solenoid valve usually used on this industry, some are hooked up on the cylinder, and a few are established subsequent to the cylinder with a bracket. Pneumatic solenoid valve can be extensively used in those excessive-danger industries, with fireplace, explosion-proof, desirable safety, pollutants-unfastened and other benefits, isn't to be had in different transmission components. The fundamental additives are divided into electromagnetic components and valve body electromagnetic components; constant core, moving core, coil. Valve body; Spool, spool sleeve, spring base.

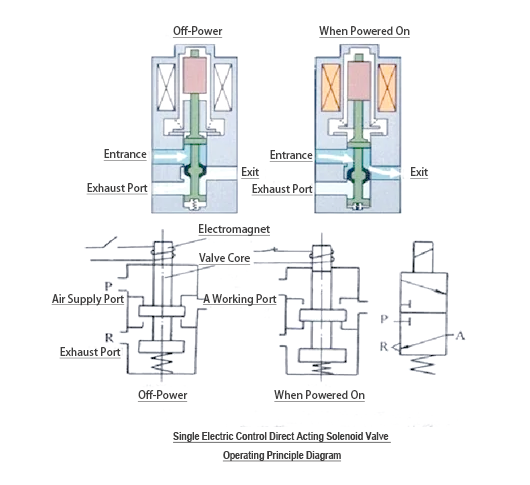

basic review of -position three-manner solenoid valve, two-position four-manner solenoid valve and -function 5-way solenoid valve. two-role three-manner solenoid valve running procedure; The coil receives strength, the coil excited the electromagnet draws, the sealing block of the charged spring on the upper a part of the shifting iron center closes the exhaust port with the assist of the spring strain, and the compressed air enters the valve cylinder from the intake port to play a controlling position. when the power is misplaced, the electromagnetic pressure disappears, the moving iron center moves downward from the constant iron center underneath the pressure of the spring, the exhaust port is opened, the consumption port is closed, and the valve cylinder changes its state because of the lack of air. two 4-way, 5-manner solenoid valve working principle is similar to the above principle, however the quantity of exhaust ports is one of a kind. The meaning of the two digits here; For the solenoid valve itself, it is power and strength loss, and for the controlled valve, it is open and near. The meaning of several passages; refers back to the wide variety of holes of the solenoid valve, get the bodily observe a look.

The energy supply of the solenoid valve has 220V electricity supply and 24V strength deliver, and 24V energy deliver is more often than not utilized in excessive-chance industries. at the whole, each has its own advantages. the use of 220V power deliver isn't always conducive to on-web page explosion protection, however is conducive to long-distance transmission. The reason is that the supply voltage is excessive, and the voltage drop because of the transmission cable will now not have an effect on the ordinary operation of the solenoid valve. using 24V strength supply is conducive to on-web page explosion-evidence, but the transmission distance is a long way, and the impact of the voltage drop of the transmission cable at the paintings of the solenoid valve have to be considered. consequently, it's far important to calculate the most allowable duration of the transmission cable according to the minimum operating voltage of the solenoid valve.

for example, the 24V strength supply is used, the minimum running voltage of the solenoid valve is 20V, the maximum allowable voltage drop of the line is 4V, the rated energy is 12W, the polyvinyl chloride insulated sheath control cable is used, the cord diameter is two.5mm2, and the two-cord system is used. The maximum length of the control cable L is calculated by looking on the table, it's far acknowledged that the maximum DC resistance of the manipulate cable is 7.1Ω/Km, and because the resistance of the voltage drop generated via the road is R = 8Ω, the maximum allowable duration of the manipulate cable is 1.079Km. And because of the use of -cord manipulate cable, so each control cable length of 539m. thru theoretical calculation, it's miles acknowledged that after the solenoid valve is not decrease than the regular running voltage of 20V, the longest line transmission distance of two.5mm2 can attain 539m.

commonplace faults occur in the course of the application of the solenoid valve

The solenoid valve connector is loose or off, the coil is burned out, and the solenoid valve is stuck. Solenoid valve wiring unfastened and fall off, this new fastening, for coil burn, see coil head LED off or insert a steel object into the coil hollow is sucked, solenoid valve coil broken alternative. For the trouble of solenoid valve sticking, put off the spool, spool sleeve and spring base, clean it up, and apply grease after cleaning. The motive is that the exhaust port isn't always geared up with a silencer, the impurities within the air enter the valve, or the compressed air is not easy sufficient, containing impurities, water, oil and other dirt.

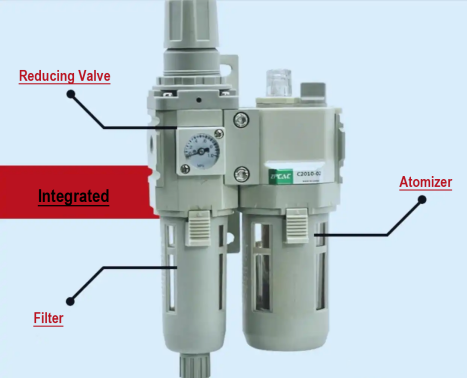

To remedy the hassle, the exhaust port of the solenoid valve isn't always installed with a silencer, and the air clear out lowering valve have to be established within the front phase of the solenoid valve intake. The advantages of the air filter pressure reducing valve can filter impurities, take in compressed air containing water, oil, and many others., to be able to purify the compressed air and keep away from pointless damage to the solenoid valve frame and cylinder.

Air filter stress reducing valve, further to the above can also be adjusted. The compressed air used in fashionable factories is 10 kilograms, this is, 1MPa. If the air clear out decreasing valve isn't installed for strain law, the harm to the cylinder is large, and it is not conducive to the control of the switching speed. underneath normal instances, the operating air supply strain of the valve can meet the switching needs of the valve at approximately zero.4MPa, so the compressed air from the air compressor station have to be depressed and altered to the pressure appropriate for the valve action, with a purpose to better guard the valve and the manipulate of the switching pace.